Label specifications are important.

While your labels might be printed perfectly, you can’t use them if they don’t comply with your automated machinery. It’s impossible to change the orientation of the labels on the roll after they are printed and changing part of your machinery to use improperly oriented labels is costly and should be avoided – plus it’s easy to do.

Determine proper specifications for your application:

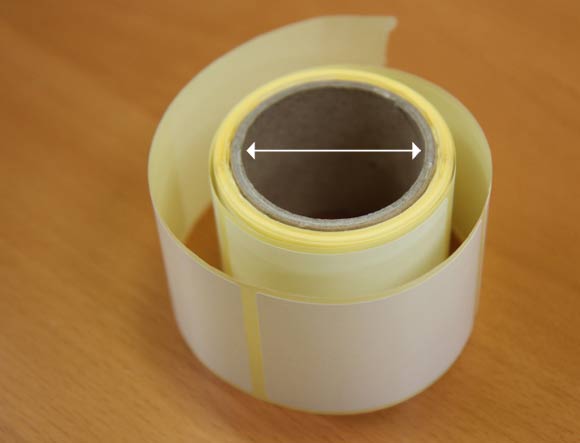

Confirm the inside diameter of the rolls. This will be determined by your labelling equipment or your staff’s work station.

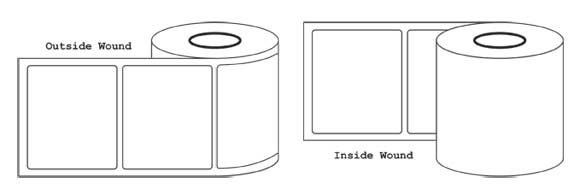

Determine if you need labels wounded on the inside or the outside of the rolls. An outside wound works fine for a general application of regular shaped labels. Some labels with very detailed shapes will require an inside wound. It will make the printing easier and make sure they don’t partially detach themselves from the roll before being applied to your products. (often the case with high-speed equipment).

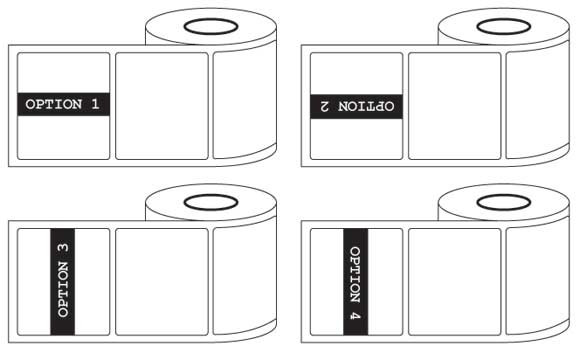

Specify label orientation using these illustrations for help. If you’re using an automated labelling machine, the orientation will depend on how the product is fed through the equipment. Is it standing up or laying sideways?

Taking care of these details before placing your order will save headaches for yourself, your workers and your print supplier.

If you’re looking for a graphic designer, please reach out and I’ll be glad to help.

Click here to contact Mr.Graphic